How We Design and Manufacture Our Rubber Ducks

Every Detail Begins at the Design Table

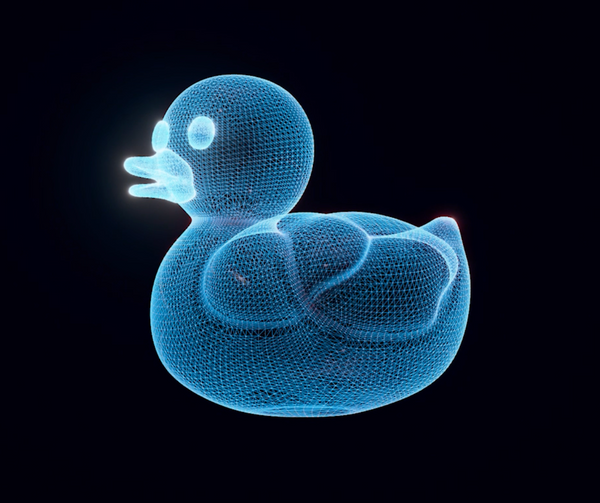

At Okie Soft Play, every rubber duck we produce starts long before plastic is poured into a mold. It begins at the design table, where we obsess over every detail — the curve of the beak, the weight balance of the body, the texture of the surface. We study prototypes carefully because small variations affect how the ducks float, stack, and ship.

Precision Mold Engineering

Once the design is finalized, we transmit detailed CAD files and 3D model specifications to our mold engineering team overseas. Mold creation is a precision process that directly affects the final product quality. Every mold cavity is cut to exact tolerances to ensure the rubber ducks maintain their shape, buoyancy, and consistent finish across production runs.

Safe, Certified Raw Materials

We use high-quality PVC or vinyl plastic compounds, selected for both safety compliance and long-term durability. These compounds are batch tested for consistency before production begins. Our rubber ducks are free from phthalates, lead, and other restricted substances, meeting both CPSC and CPSIA compliance standards for child safety.

Controlled Injection Molding Process

During production, raw plastic is heated and injected into precision steel molds under controlled temperature and pressure cycles. This ensures even wall thickness, consistent color saturation, and smooth, uniform surfaces. We monitor every production lot for shrinkage, molding defects, and flashing to keep rejection rates extremely low.

Detail Finishing & Custom Printing

Once molded, each duck moves into the finishing process. Details such as painted eyes, logos, or custom prints are applied using heat transfer film, pad printing, or direct digital UV printing, depending on the complexity of the design. Every step is monitored for adhesion quality, color matching, and long-term durability.

Final Inspection and Packaging

Before shipment, all ducks pass through final visual inspections, vacuum tests for leaks, and packaging audits. Our packaging is designed for both retail display and safe transit through the international freight process.

Global Shipping and Distribution

The finished rubber ducks are palletized, loaded into export containers, and shipped to our U.S. distribution warehouse where final spot checks are conducted before fulfillment to Amazon, Walmart, Shopify, and other online marketplaces.

We Control the Entire Manufacturing Process

Unlike mass-produced commodity ducks, we actively control every stage of the manufacturing cycle — from CAD design to injection molding to custom packaging. Our goal is simple: to produce high-quality rubber ducks that meet safety standards, maintain consistency across thousands of units, and deliver a product our customers can confidently resell or gift.

Rubber Duck Safety FAQ

Are your rubber ducks safe for babies and toddlers?

Yes. All of our rubber ducks are made from child-safe, non-toxic materials and tested to meet CPSC/CPSIA compliance. They are free from lead, BPA, phthalates, and harmful chemicals.

What materials are Okie Soft Play rubber ducks made from?

Our ducks are produced from soft, durable vinyl plastic, designed for bath time and soft play use. Each batch is inspected for chemical safety and structural durability during production.

Do your ducks meet international safety standards?

Yes. In addition to U.S. safety testing, many of our ducks comply with international standards, including EN71 (Europe) and ASTM F963.

How do you test your rubber ducks?

Our factory performs full compliance testing on materials and finished products, including lead content, phthalate levels, mechanical strength, and small parts safety. Test reports are reviewed before each production run ships.

Can I request safety certificates for my order?

Yes! We can provide CPC (Children’s Product Certificate) documentation for wholesale and retail orders upon request. Contact us directly at chris@softplaystore.com.